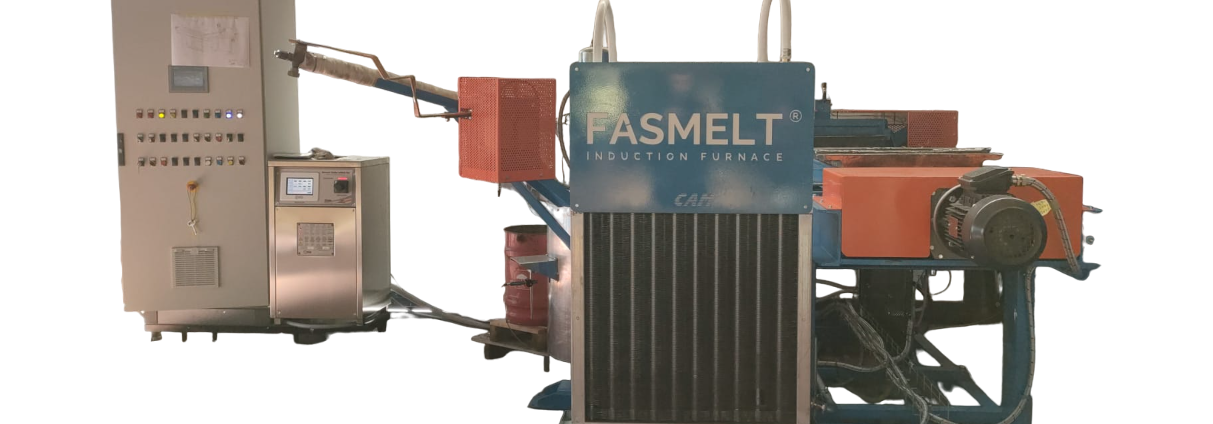

Thanks to FASMELT you will produce at lower costs and with greater safety

The BCI convention ended a week ago.

A spectacular event, of high technical depth.

In this event, every year there is an award ceremony for technical innovations in the lead-acid battery industry:

The BCI Innovation Award in honor of Sally Breidegam Miksiewicz recognizes innovations within the battery industry that align with the guidelines of sustainability, safety, cost, performance, uniqueness and value.

We presented ourselves with the FASMELT: the rapid melting furnace that has many advantages:

– fast melting time

– without CO2 emissions

– reduced waste

– 60% less consumption compared to a traditional oven

The award was won by ENTEK International

But I was surprised by the many people who flocked to our booth after the FASMELT video was broadcast.

For privacy reasons YouTube needs your permission to be loaded. For more details, please see our Privacy Policy.

I AcceptI didn’t expect that many managers would be impressed by the new system of melting lead, in a way that is safe for operators, without emissions, and energy saving.

Today the lead battery industry has many challenges to face, but the first is:

-

workers’ lead intoxication

-

emissions

-

production costs

Before talking about the benefits of producing lead-acid batteries with a FASMELT, it is good to remember what the limitations are today regarding the production of lead-acid batteries:

Workers’ lead intoxication:

“The new rules include a revised binding workplace occupational exposure limit for lead in air of 0.03mg/m3 and a biological limit value for lead in blood of 15µg /100ml.

There is new guidance to protect female workers of childbearing age.”

Source BESTmag

These are the new laws in Europe, but in the US not much changes.

Many companies are implementing new internal rules to reduce lead levels in the blood:

– ban on smoking cigarettes

– closed helmets

– limited access in certain areas

The fact is that the problem remains, in all these actions there is none that eliminates the emission of lead into the air.

Emissions problem

“From October, the CO2 levy‘s trial phase will require companies importing steel, cement, aluminium, electricity, fertilisers and hydrogen into the EU to report the emissions involved in producing those goods.

Companies will face penalties of up to 50 euros per tonne of CO2 if they don’t report. From 2026, there will be a CO2 fee applied to goods brought into the EU.”

Source Reuters

I quote this part of the article to summarize the fact that in Europe there will be increasingly stringent limits on industrial emissions.

The same applies to other continents as well.

Problem of production costs and emissions:

Countries that purchase gas are subject to the vulnerability of the gas price (see how it went in 2021/2022), in addition to the fact that emissions of CO2 and other gases are increasingly higher.

Is there a solution?

Yes.

-

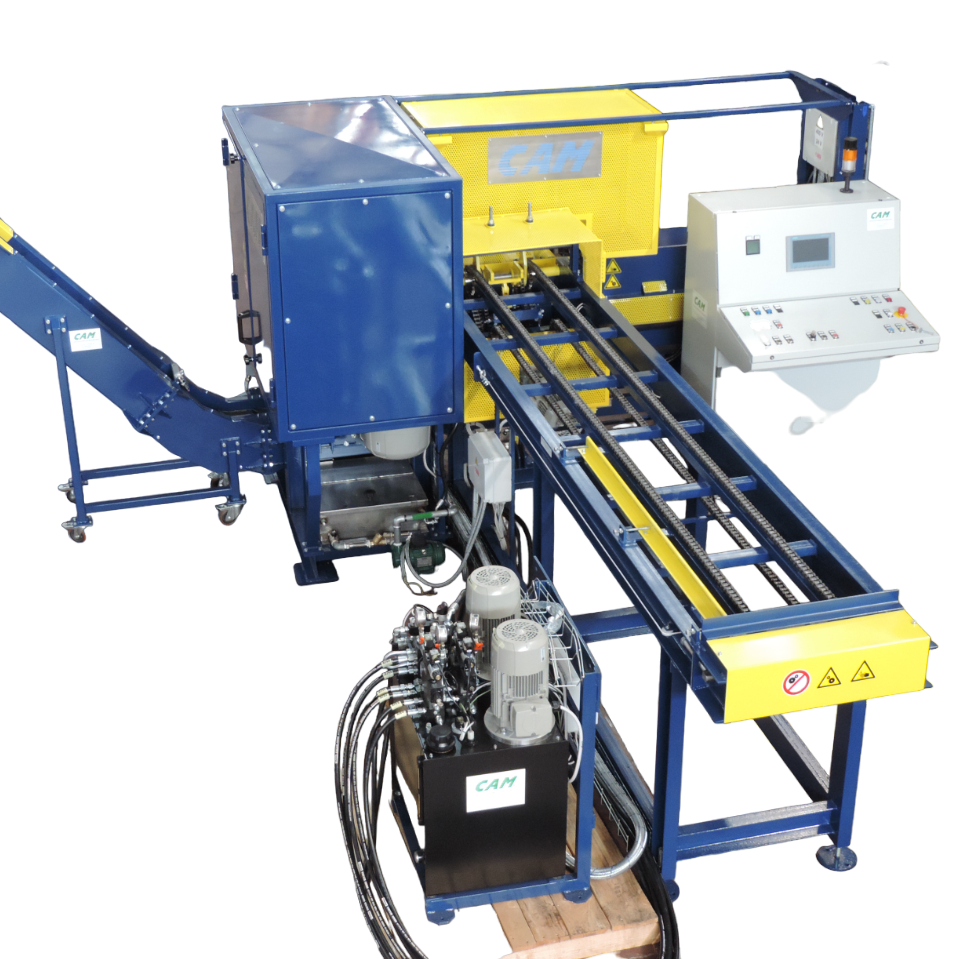

LEAD SHAVER

-

FASMELT